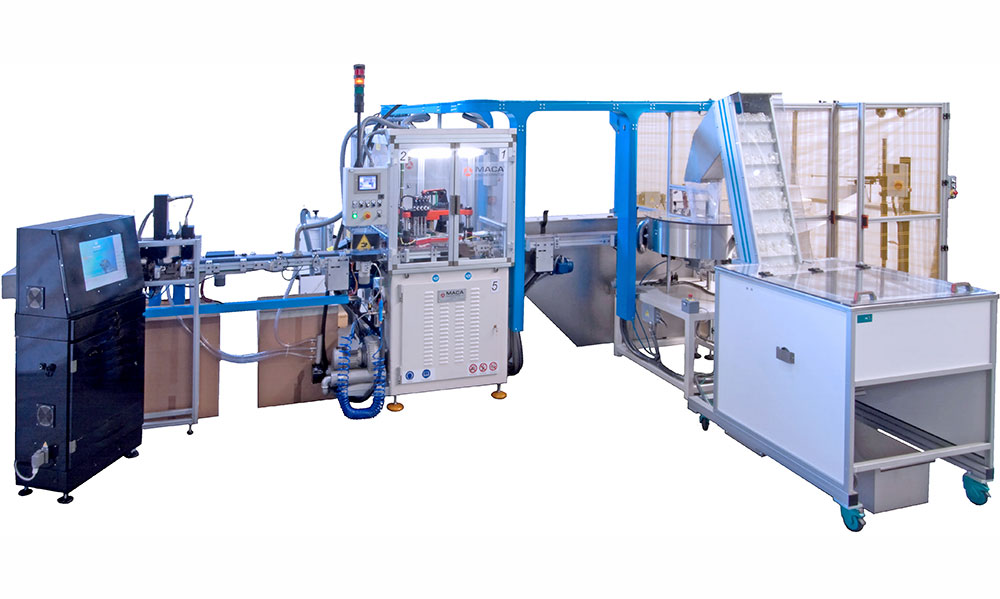

Type ITVE-MRR-IRV line for cutting the tamper evident ring, folding the inner flap of plastic caps and inserting pre-cut liners pre-stacked in tube.

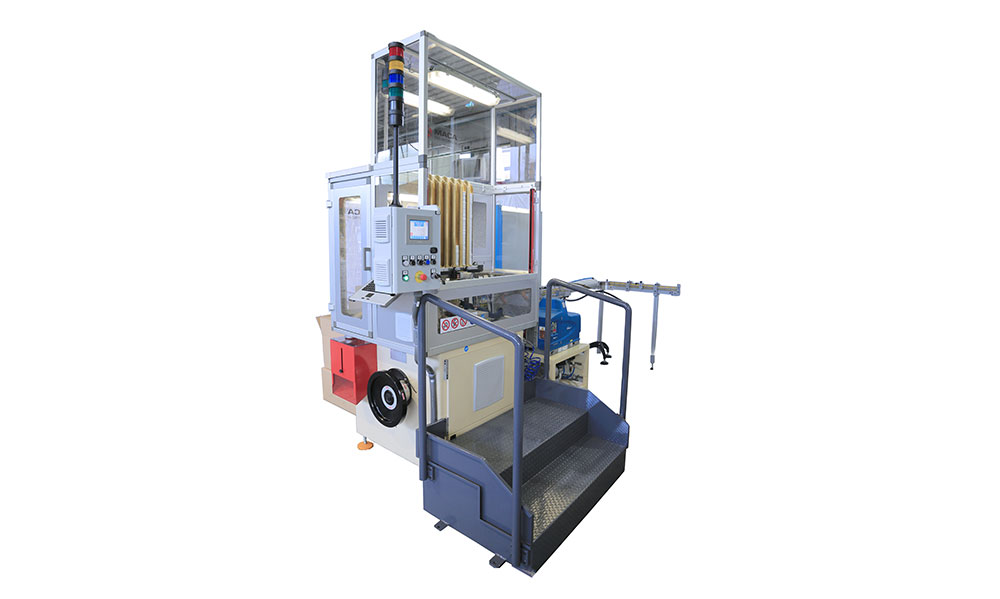

First machine type ITVE-MRR with first flywheel dedicated to cutting the tamper evident ring and second flywheel (optional) for folding the inner flap.

Loading and discharging stars synchronized with the main flywheel and photocells;

External slitting blade for quick replacement;

Possibility of processing caps having different diameters without having to replace the gears;

Second machine type IRV for inserting pre-cut liners pre-stacked in tube inside the cap.

Exit conveyor belt with the possibility of installing a vacuum system to allow integrating a vision system (cameras not included); Box diverter for loading 2 boxes.

Options: Quality inspection system (cameras excluded); ionization and dust aspiration system; noise reduction enclosures; box diverter for loading 4 boxes or automatic box conveyor.

The machine complies with European safety laws (CE).